Rock mechanics testing laboratory

Institute operating the laboratory: Department of Mining and Geotechnical Institute

Professional head of the laboratory: Dr. Ákos Debreczeni, associate professor

Load-bearing equipment (crushing machines) form the backbone of the rock mechanics testing laboratory operating in the basement of the A/4 building of our university.

The oldest crushing machine still in operation today is the 25 kN machine, which was manufactured at the Material Testing Equipment Factory in Budapest in 1958. Its maximum load capacity is 25 kN.

The machine with a measuring limit of 100 kN also dates from the sixties, and was also made at the Material Testing Equipment Factory.

The third, 1,000 kN load machine dates from 1965 and was manufactured in Leipzig, the former GDR. This machine is suitable for both tensile and compressive stresses up to 1000 kN.

In the rock mechanics laboratory in the basement of building A/4, on the first floor, Hottinger Baldwin Messtechnik load cells, single-channel measuring amplifiers, and inductive tactile sensors were purchased. In the second stage, HBM's Quantum X measurement amplifier and signal processing system, and the associated QuantumX, or Catman Easy

The newly created rock mechanics laboratory of building C/2 (workshop hall) was equipped with the following equipment: Controls triaxial testing equipment capable of producing 700 bar lateral pressure with Hoek triaxial cells, and Controls 3000 kN, 250 kN and 15 kN presses, and a bending machine with a nominal load capacity of 150 kN with the corresponding control software, Advantest 9 hydraulic operating unit, workstation and Sercomp 7 automatic control console.

Noise-vibration measurement laboratory

Institute operating the laboratory: Department of Mining and Geotechnical Institute

Professional head of the laboratory: Dr. Zoltán Virág, associate professor

Learning about the measurements needed to recognize the environmental impact of noise and vibrations should continue to be emphasized in your technical geoscience training. The use of measured quantities in assessing and solving environmental protection problems.

The volume and design of the room allows smaller student demonstration measurements to be conducted. The teaching experience shows that the learning of this subject, which has a significant theoretical background, is facilitated by laboratory demonstrations and measurements. Here, the aim is mainly to present the noise parameters typical of the sources through measurement. Also, that the students can get "close to the instrument" and get to know its parameters, the importance of the settings and their effect on the results of the measurements. In this way, they will be able to safely perform the basic measurements that produce the noise parameters required during their later industrial activities. (E.g. different sound pressure levels, noise power level of a device).

We would also like to install here the measurements of Measurement Techniques, Maintenance diagnostics, which show one of the effective tools of predictive machine maintenance.

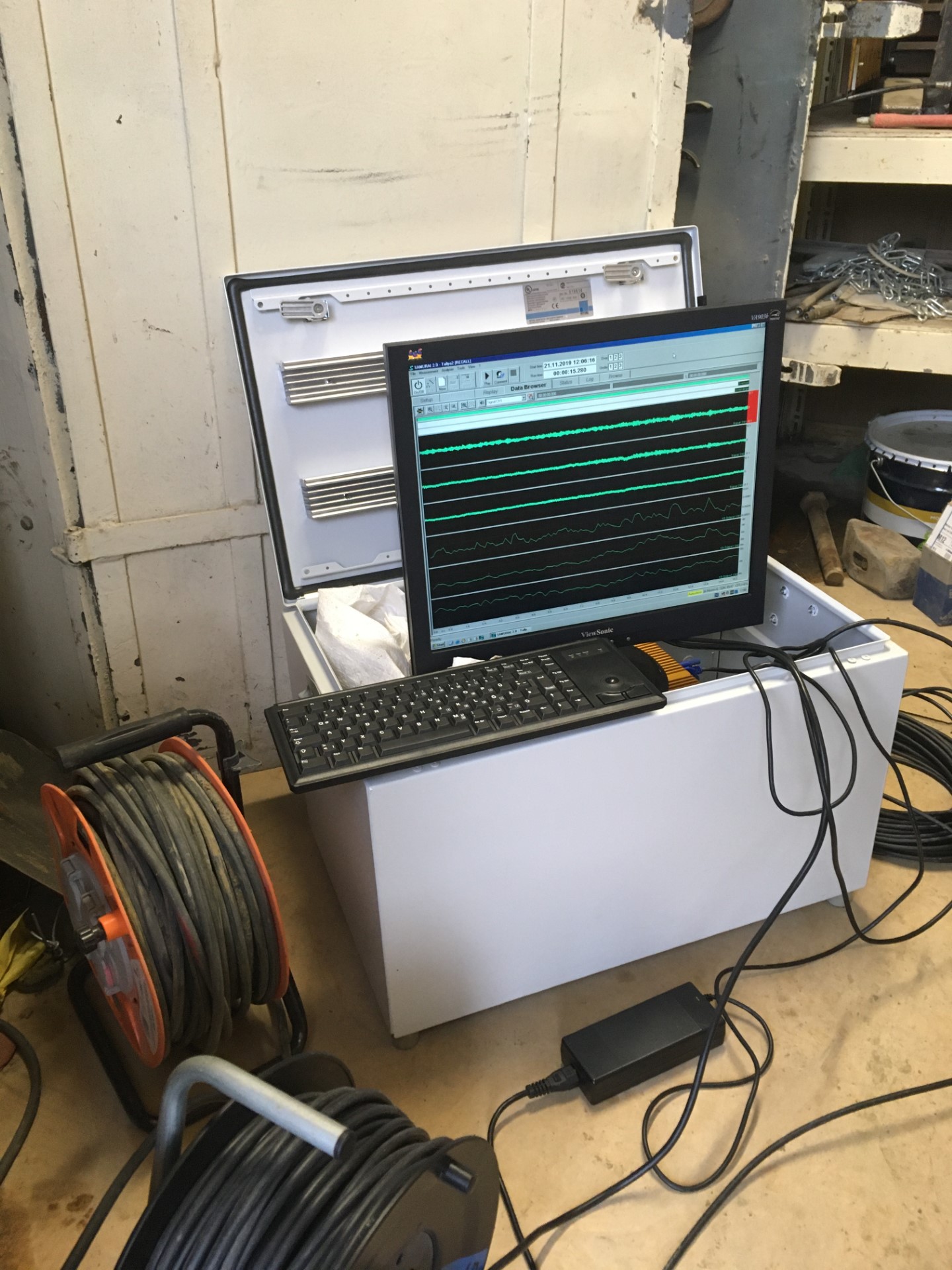

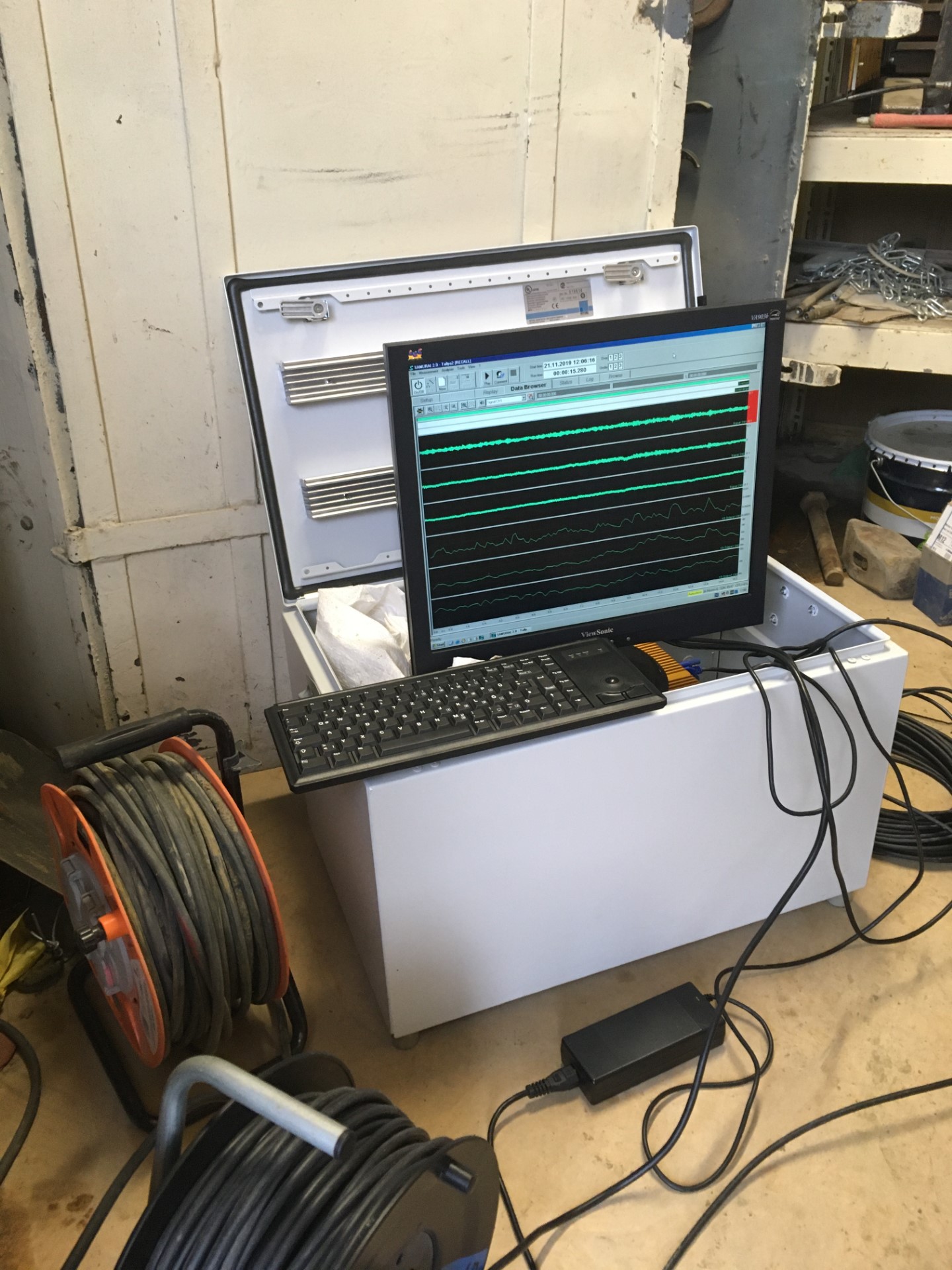

The measurement of the seismic effect of industrial explosions is also integrated into this lab, which students can learn about in the course of the Blasting Techniques course. During the seismic tests, the students can gain knowledge on the instrumental examination of various vibrations. We have a measurement system equipped with a computerized data logger available for the measurements. The geophones measure the vibration acceleration according to the three directions of the space and form the vibration speed in each direction, as well as the value of the resulting vibration speed.

In addition to these, the department currently has a request for vibration and noise testing of conveyor rollers, which we also teach within the scope of the Conveyor Machines subject.

|

Tests, experiments and services that can be performed in a laboratory:

Vibration diagnostic examination of machines. (also in the field)

Determining the noise output (level) of machines. (also in the field)

Examination and assessment of the state of wear and tear of machines and machine parts.

Measurement of noise emissions of industrial objects. (local)

Measurement of noise exposure to workers. (local)

Measurement of the seismic and acoustic effects of industrial explosions. (field)

Laboratory equipment:

B&K 2526 type. vibration analyzer (off line), SENTINEL 7107 software

B&K 2232 type. noise meter

B&K 2236 type. integrating noise meter B&K 4443 type. noise dosimeter

Type PULSE 3560-T-01. hardware suitable for noise and vibration measurements,

LabShop PC software

LeCroy 140 type. sampling oscilloscope

SPIDER 8 measurement data collector, CATMAN PC software

Hurricane 12ch measuring system

IMI PCB M604B31 Triaxial Accelerometers

SAMURAI Vibration Bundle, Building Vibration, Post

O-Pitblast blast planning software

FLIR B Series Thermal Camera

|

|

Gas technology laboratory

At the Gas Engineering Department of the University of Miskolc, in the early 1980s, with the support of the gas industry, a gas industry education laboratory was established in accordance with the standards of the time. However, due to the lack of financial resources, the regular renovation and modernization was not carried out, and the laboratory became completely obsolete both physically and morally. The laboratory exercises thus shifted more and more towards only theoretical training. In recent years, however, a change has occurred, as the system of support for vocational training has been established, and thus it has become even easier for gas industry companies that consider education to be a matter of their heart to "implement" the support. The first grants arrived in 2002, and the laboratory has been continuously developed since then. After the complete architectural and building engineering renovation, in 2004 it was possible to create a measuring wall for gas appliances for practical training.

Purpose and tasks of the laboratory:

The teaching laboratory performs two main functions. On the one hand, there is an educational section suitable for 14 people, where students can learn the theoretical knowledge related to measurements, the collection of gas industry specialist materials and the sections used for education are also located here. In the other part of the laboratory, a gas appliance measuring wall consisting of five measuring points has been set up, where the students have the opportunity to learn about the structure and operation of modern gas appliances, and it is also possible to measure the appliances' heat and combustion technology (determining heat balance and efficiency). The laboratory enables the practical training of students and the carrying out of certain research related to gas appliances (e.g. comparison of measurement deviations of different types of gas meters, changes in the performance of gas appliances related to changes in network pressure, changes in combustion parameters in the case of gas stoves, gas convectors, wall-mounted boilers and water heating equipment). Moving on in order, there are the measuring units of a domestic gas stove, a chimney gas convector, a wall-mounted gas boiler and a flow-through water heater. All measuring stations are equipped with instruments that ensure simple readings and enable digital data collection. The digital signals are stored in a central data collector, based on which data the measurements can be easily evaluated for the students.

Laboratory equipment, technical characteristics:

In addition to measuring temperature, pressure and quantity, it is also possible to use hand-held measuring instruments built into the laboratory on the water and gas side, enabling digital data collection and central processing. The laboratory has a Spectra 2000 type portable flue gas analyzer, an MRU Vario Plus type biogas analyzer, a Roline 305 type probe and a Raytec MT4 type infrared temperature sensor. Also available for measurements are GMH 3110 type barometric and overpressure measuring instrument, TA35 type hot wire air velocity meter, 300 HC type gas content meter, SP100 type electronic scale, TESTO 317-2 type manual gas leak detector, TESTO 317-3 type manual CO detection equipment and a laser rangefinder (up to 12 m). The laboratory also has a TESTO 875-2 type thermal camera as well as a TESTO 319-1 type endoscope device, which helps to examine the structural elements of gas equipment. Hand-held instruments are also suitable for on-site inspection and analysis of gas appliances and for determining their operating parameters. From the safety point of view, a gas detection device and an artificial combustion product removal system were installed, which also serve to educate the students.

During the development of the concept, it was particularly important to observe and comply with safety technical parameters, since the laboratory is located on the ground floor of a five-story building, and in addition, a lower neighboring building wing is located very close. From the safety point of view, a gas detection device has been installed, and the combustion products are also artificially removed from the room. The measuring positions are electrically interlocked, so only one device can be measured in the laboratory at a time. Unfortunately, the existing facilities of the room limited the possibilities, but despite this, we believe that we have succeeded in creating a gas technology measurement laboratory at the University of Miskolc that meets the technical standards of today and is suitable in all respects.